Process

Procurement from Local Vendors

Collection Points

Scrap is collected from various local sources such as households, businesses, construction sites, and industrial facilities

Sorting and Pre-Processing

Local vendors often handle initial sorting and processing to ensure the scrap meets quality standards before transportation.

Transportation

Scrap is transported from local vendors to your sorting and processing facilities.

Importing Good Quality Scrap from Various Countries

Sourcing

Identify and establish relationships with international suppliers who can provide high-quality scrap. This involves market research, attending trade shows, and leveraging industry networks.

Compliance and Regulations:

Ensure compliance with international trade regulations, including import/export laws, tariffs, and environmental regulations. Quality Assurance: Implement stringent quality checks at the source to ensure the imported scrap meets required standards.

Logistics and Shipping

Arrange for the transportation of scrap via sea, air, or land, depending on the most cost-effective and reliable method. This includes managing shipping documentation and coordinating with customs brokers.

Receiving and Inspection

Upon arrival, the imported scrap undergoes inspection to verify quality and quantity against the purchase agreements.

Creating steel strips from scrap metal involves several key steps in-house, from melting scrap to the

final rolling process. Here’s a detailed breakdown

Continuous Casting Machine (CCM)

Molten Metal Transfer

Transfer the refined molten metal from the furnace to the continuous casting machine (CCM) using a ladle.

Mold Casting

Pour the molten metal into the CCM mold. The mold is water-cooled, solidifying the outer shell of the molten steel while the core remains liquid.

Primary Solidification

The partially solidified metal, now called a billet, bloom, or slab (depending on the cross-sectional shape), exits the mold and is continuously cooled and solidified.

Cutting to Length

The continuous casting process produces long strands that are cut to the desired length for further processing.

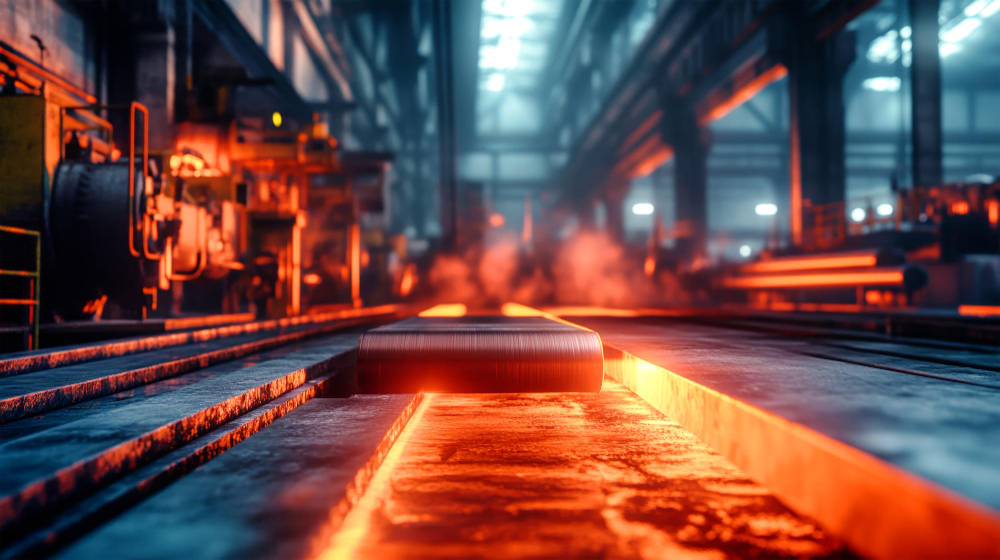

Rolling Mill

Pre-Heating

If needed, pre-heat the billets, blooms, or slabs in a reheating furnace to the required temperature for rolling.

Rough Rolling

The pre-heated metal is passed through roughing mills to reduce its thickness and shape it into intermediate forms.

Intermediate Rolling

Further rolling stages refine the shape and dimensions, gradually reducing the metal to the desired thickness.

Finishing Rolling

The final rolling stages produce steel strips of uniform thickness and width, achieving the required mechanical properties and surface finish.

Cooling

Cooling

After the final rolling, the steel strips are naturally cooled to achieve the desired microstructure and mechanical properties.

Quality Control

Inspection

Conduct thorough inspections and testing to ensure the steel strips meet the required specifications. This includes checking for surface defects, dimensional accuracy, and mechanical properties.

Testing

Perform mechanical tests (tensile strength, elongation, hardness) and chemical analysis to confirm the material’s quality.

Packaging and Distribution

Shipping: Distribute the finished steel strips to customers or further processing facilities